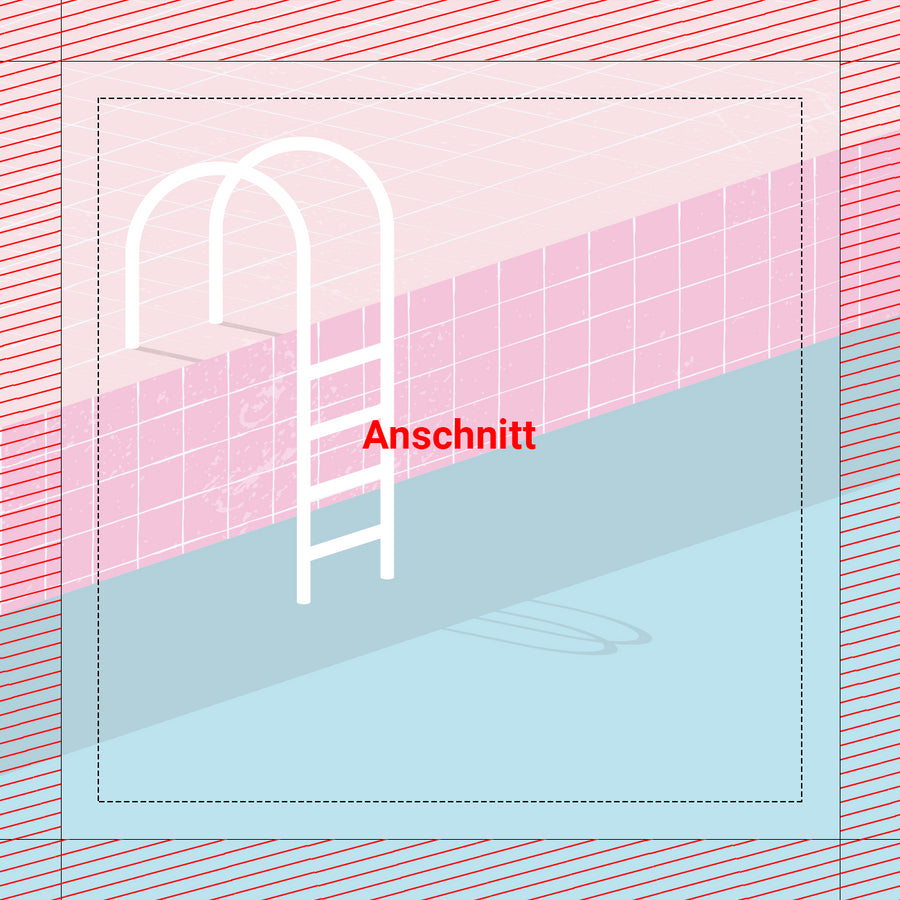

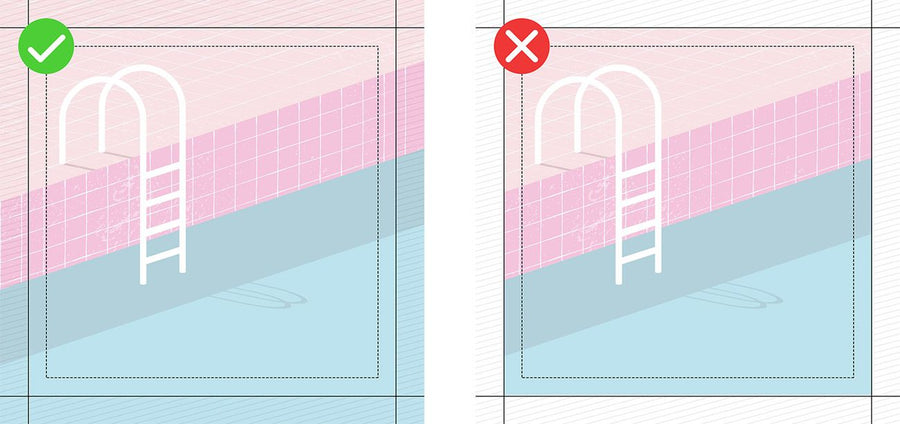

What exactly is a bleed? How do I create the perfect design? And what do I need to consider when exporting my data to achieve optimal print results? As experts in backlit print designs, we know our customers' questions – and we know the answers.

Quick assembly without tools.

Save time and personnel. Thanks to the modular plug-in system, assembly is intuitive and quick, without the need for tools or technicians.